GEOGRID

Polypropylene PP Biaxial Geogrid Factory Price

Biaxial geogrid is made of high molecular polymer through extrusion, forming and punching before longitudinal and lateral stretching. This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforcement

material.

Item | value |

Type | Geogrids |

Warranty | More than 5 years |

After-sale Service | Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement |

Project Solution Capability | graphic design, 3D model design, total solution for projects, Cross Categories Consolidation |

Application | Other |

Design Style | Traditional |

Product name | PP biaxial geogrid |

Color | Black |

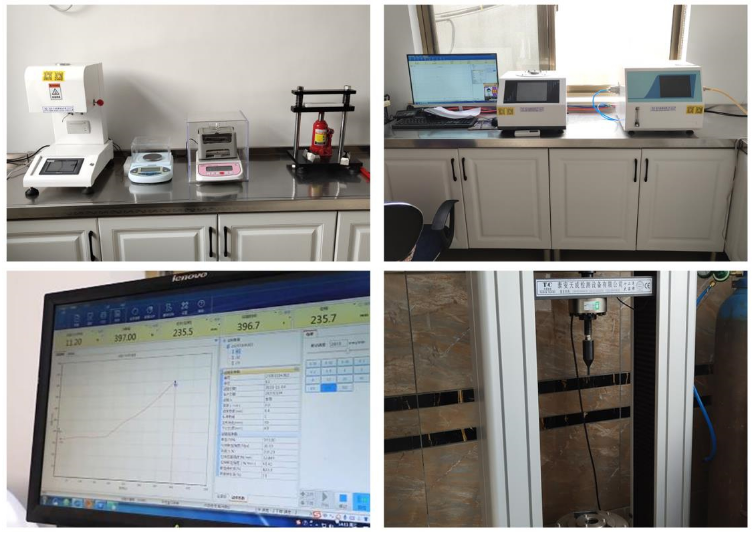

Certificate | ISO9001 ISO14001 |

Feature | High Tensile Strength |

Keywords | Geogrid |

Application | Road Construction |

Material | 100% PP (polypropylene) |

Tensile strength | 15-50kN/m |

Width | 1-6m |

LENGTH | 50-100m |

Geogrids focus almost entirely on reinforcement applications, although separation may be a function. The following are examples of a few applications.Slope Reinforcement- embankments over soft soils, extra-steep earthwork slopes, landfill liner systems, and industrial and contaminated land reclamation Base Reinforcement- foundations of roadbeds, parking lots, railroad tracks beds, airports runways, permanent unpaved roads,construction haul roads Wall Reinforcement- retaining walls, sea walls, airport noise barriers, and bridge supports Berm Reinforcement - spillway channels for earthen dams, levees, and waste contaminated ponds, banks for earthen canals and waterways.

Geogrid can be used in railway, highway, sports hall, dam, water conservancy, tunnel, coastal beach, reclamation, environmental protection and other projects.

Features:

1.High tension resistance, high plane torsion resistance modulus, good creep resistance and stable chemical nature.

2.High mechanic damage resistance and durability and large friction factor with sandy stone.

3. Improve the bearing capacity of the roadbed and extend the service life of the roadbed.

4. It can decrease 30%-40% of filling thickness for reaching same effect, save cost.

5. Convenient construction, saving effort, shortening construction period and reducing maintenance cost.

6. Strengthen soil slopes to prevent soil erosion.

7. Can replace metal mesh, used in coal mine underground false roof network.

8. Supporting the stability of grass slope mats, greening environment.

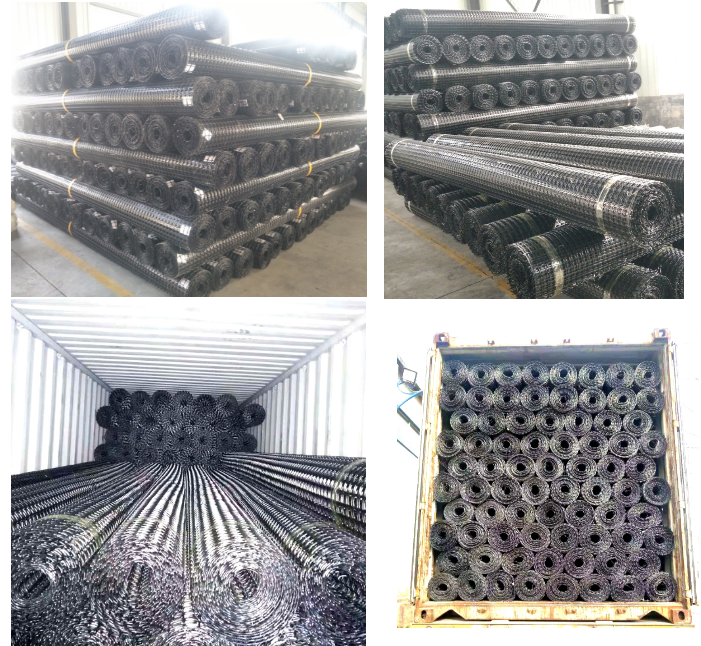

Packing & Shipping:

Production:

- last:no more

- Next:no more