Geosynthetics and Technology

In his recent report "New Frontiers in Geotechnical Engineering - Challenges and Opportunities", J.K. Mitchell, the keynote speaker of the Terzaghi Lectures (1984) and the Rankine Lectures (1991), pointed out: "In the early 1950s, meeting the Geotechnical engineering is only the second-level discipline of civil engineering, ... focusing on soil mechanics and foundation engineering, ... Since then, the scope of geotechnical engineering has continued to expand, and the branch disciplines of geotechnical engineering have become more and more many". He listed the main new research fields and progress of geotechnical engineering in roughly chronological order in the past 50 years, including "environmental geotechnical engineering, geosynthetics, soil reinforcement, ... ". A special mention is made of "earthworks, a variety of geosynthetics and composites, which have become almost routine". It shows that geotechnical engineering has developed into a university with many branches and technologies, and geosynthetics is one of the important branches.

The following is a brief review of the development of this branch, its expansion in my country, and its status quo.

1. A brief history of geosynthetics and their development

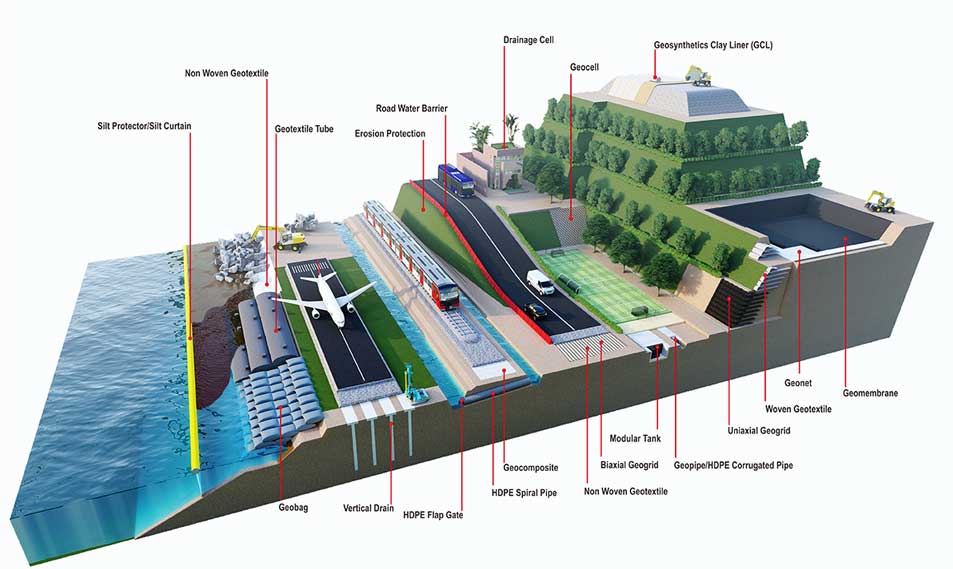

Geosynthetics is a general term for various products used in geotechnical engineering made of high molecular polymers as the basic raw materials, and also refers to the engineering application technology of these products. The products include four categories of permeable geotextiles, basically impermeable hdpe geomembrane roll, geocomposite materials and geotechnical special materials, with hundreds of varieties. Geosynthetics have emerged with the development of chemical industrial polymers and engineering expansion, and their application technology depends on the basic principles of geomechanics. Dr. Giroud, J.P., one of the founders of the discipline, once hailed it as "probably an important revolution in the history of geotechnical engineering".

The exact age when geosynthetics began to be used has been difficult to verify. But the outline can be seen from some early landmark engineering cases. From about the 1930s, polyvinyl chloride (PVC) geomembranes have been used for anti-seepage in swimming pools; the United States Bureau of Reclamation began to use polyethylene (PE) membranes for anti-seepage in channels in 1953; the former Soviet Union also used anti-seepage in channels earlier. Lay Low Density Polyethylene (LDPE) film; In 1992, in order to repair the leakage of the Alpe Gera concrete dam with a height of 174m built in 1964, a PVC film with a thickness of 2.2mm was laid upstream of the dam surface. In 1958, the state of Florida in the United States spread geotextiles as filter pads under the coastal stone slope protection, which is considered to be the beginning of the application of modern geotextiles. It is particularly worth mentioning that the Netherlands suffered a severe storm from 1952 to 1953, causing heavy loss of life and property. After the disaster, the famous delta project was launched. According to statistics, 10 million m2 of early geotextiles were used, which greatly promoted the development of geotextiles. In 1968, the Netherlands developed a fabriform made of double-layer geotextile for revetment.

In 1968, the French Rhone Poulenc company first created a non-woven geotextile, which can replace the traditional sand and gravel material as a filter layer, which expanded the application field of the geotextile; in the early 1980s, the British Mercer invented the Geogrid is still the best material for soil reinforcement. In the late 1970s, the prefabricated strip drain developed on the basis of the cardboard wicks proposed by the early Swedish Kjellman, without the need for sand, can be widely used to replace sand wells to accelerate the consolidation of soft foundation drainage. In addition, geotubes with large diameter (3-5m) and large length (tens of meters to 100 meters) made of textiles can accommodate dredged sand, silt, etc., dehydrate and consolidate, forming The continuous large-volume strip soil tube bag can not only be used as an anti-scour wall on the shore, but also can be built into a river spur dam, a dam, and even reclaimed land, or built an artificial island. In the late 1980s, the Netherlands, Germany, France, the United States and Japan successively used high-strength woven geotextiles or prefabricated, or made large-volume geocontainers on open-bottom ships (geocontainers, some of which have a single volume of two or three thousand m3). Holds waste, dredged soil, etc. After it is closed, it will be transported to the designated water area by the GPS positioning system to open the bottom of the ship, build an underwater stable platform, a breakwater, etc., or control seabed erosion and build a submersible dam structure (Sill structure). In order to improve the ecology and protect the environment, various three-dimensional geonet mats made of thermal adhesive resin as raw materials have come out one after another, which can be used for planting grass on slopes, and even bare rock slopes can be covered with green clothes. Today's environmental protection issues are highly valued, not only the geomembrane and application technology of anti-seepage materials have been greatly improved, but also contributed to the successful development of another anti-seepage material, GCL (Geosynthetic Bentonite Cushion), which is widely combined with geomembrane. Anti-seepage systems for landfills. Recently, it has been gradually promoted to hydraulic anti-seepage, used in channels, pools and artificial lake scenic spots.

Geosynthetics are called the fourth major building material after wood, cement and steel. Their application satisfies the need to solve the three major problems of soil stability, deformation and seepage mainly involved in geotechnical engineering. To sum up, they have the following functions that are often required in engineering: (1) filter function; (2) drainage function; (3) isolation function (such as laying geotextiles between the railway foundation and the under-track ballast, that is, It can prevent the ball slag and gravel from being pressed into the foundation or the fine soil particles of the foundation to be sucked into the ball slag, extending the service life of the roadbed); (4) Reinforcement function (widely used in the construction of steep slopes, reinforcement of soft foundations and construction of reinforced soil retaining walls, etc. ); (5) anti-seepage function; (6) protective function (such as anti-wave and anti-scouring of rivers, lakes and seas, anti-cracking of roads, anti-frost heave of bank slopes and retaining walls); (7) containment function (using this material to make into large-volume bags, tube bags and small bags, boxes, cages, etc., to accommodate bulk materials to build dams, reclamation and land, etc.).

A geosynthetic material often has multiple functions, and it should meet its main functions when designing, but also need to take into account its side effects. Geosynthetics and soil constitute composite soil, and its stress-strain properties are analyzed and studied, mainly based on the principles of soil mechanics, hydraulics and engineering geology, combined with consideration of polymer properties and their interaction with soil. At present, many design methods have reached consensus, but since the mechanism of the co-working of materials in the composite has not been fully understood, some verification models still need to be improved.

In order to exchange technology and learn from each other, the International Geosynthetics Society (IGS) was formally established in 1983. There are also regional societies in Asia, Europe, North America, and South America. Starting from the 1st International Symposium held in Paris in 1977, the International Symposium was held basically every four years, and the 8th International Symposium was held in Yokohama, Japan in September 2006.

2. Progress and status quo of geosynthetics technology in China

In the late 1970s, the Third Plenary Session of the Eleventh Central Committee of the Communist Party of China established the epoch-making "reform and opening up" policy, which changed the situation of my country's long-term isolation from foreign countries and opened up a smooth channel for foreign scientific and technological exchanges. After more than 20 years, with the joint efforts of production units, scientific research and teaching institutions and product manufacturers, especially the establishment of the cross-industry "Geotextile Science and Technology Information Cooperation Network" at the end of 1984, the technology of geosynthetics has been in line with international standards since the beginning. A considerable-scale industry team has been established, so that scientific research, production and application have reached a certain level. The development process and current situation can be briefly described as follows:

1) Development process

The progress of this technology in my country can be summarized into four stages.

(1) Spontaneous application period

As early as the 1960s, the Dayuzhang Irrigation Area in Shandong Province and the Shengli Canal in Henan used plastic films as anti-seepage channels, and were later popularized for leakage prevention in reservoirs and reservoirs; The membrane is used to prevent cracks and leaks on the upstream surface of the concrete buttress dam; in 1976, the neighboring horses on the bank of the Yangtze River in Jiangsu were weighed with flat geotextiles combined with concrete blocks to make soft sinkers to prevent the river bank from scouring and collapsing; The ground anti-shock problem is solved with a similar software row. The characteristic of this period is that the material is used in individual projects, neither products with certain specifications nor stereotyped design methods are used.

(2) The period of technology introduction

Reform and opening up have created opportunities for domestic and foreign technical exchanges. In the early 1980s, the Academy of Railway Sciences first accepted 20,000 m2 of spunbond non-woven geotextiles donated by DuPont in the United States. It was tried to treat the long-standing muddying disease in railways, with a success rate of more than 90%. The beginning of formal geosynthetics. Inspired by imported products and initiated by Chinese textile colleges, the trial production of the most widely used needle-punched non-woven fabrics has been started. Although manufacturers from the United States, Austria, France and other countries were stationed in my country at that time, the high cost of imported goods and the difficulty of foreign exchange greatly promoted the development and growth of domestic products.

Plastic drainage belts were introduced from Japan in the early 1980s. The Research Institute of Tianjin First Aviation Administration, East China Institute of Water Conservancy and Tianjin Aviation Administration cooperated to imitate the domestic drainage belt. First of all, an area of 480,000 m2 was applied in the Tanggu Xingang East Jetty, replacing the bagged sand well. Later, the vacuum preloading method was developed. By 1988, the adoption amount exceeded 10 million m2.

In the same period, the geo-model bag was introduced, which was first used in the approach channel of Taizhou Ship Lock, Jiangsu, and was localized by Wuxi Wool Textile Dyeing Factory. In 1988, it was also used as a seawall revetment when the flow velocity in the strong tide area at the Qiantang River Estuary in Haining, Zhejiang was 8.3 m/s. Later, the product developed a hinged mold bag, which can allow a certain movement to adapt to the deformation of the foundation.

In 1983, reinforcement technology and reinforced geogrid were introduced. By the mid-1990s, it had researched and produced domestically produced products on its own.

In the early 1980s, low-pressure drainage and water-conveying plastic pipes, including ground hoses and buried hard pipes, were introduced, which were rapidly popularized in northern my country where water sources were scarce.

During this period, inspired by foreign technologies and products, material manufacturing, testing and applied research and design have made great progress. Test equipment and procedures have been developed to cover the physical, mechanical, hydraulic and durability aspects of materials, although the specifications are quite inconsistent. In terms of products, except for a few special materials, most of them have met domestic needs. The processing procedures and specifications of needle-punched non-woven fabrics have been studied, and the anti-aging, anti-static and anti-slip properties of PP woven fabrics have been developed, and adhesives have been developed into materials, etc. . The pore size determination of fabrics, the criterion of reverse filtration, the mechanism and prevention of mud and mud in the subgrade, the discussion of the capillary action in the cut soil of the fabric, the crack prevention of the road, the treatment of expansive soil with geomembrane, the experimental study of centrifuge and the analysis of soil by finite element method Body reinforcement, etc. In terms of technical education, many key colleges and universities have begun to train master and doctoral students in geosynthetics and offer technical courses. From the end of 1984, the irregular internal publication "Geosynthetics Science and Technology Newsletter" has been published, and 182 issues have been issued so far. In 1986, the first "National Geosynthetics Academic Conference" was held in Tianjin, and many foreign experts attended. In the future, the National Conference will be held every four years, and six times have been held so far.

(3) The period when the organization was established

At the end of 1984, with the advocacy of Liu Zongyao, the then deputy director of the Hebei Provincial Department of Water Resources and a water conservancy expert, and the support of famous geotechnical professors Huang Wenxi and Lu Zhaojun, the "Geotextile Technical Information Network" was established. Subsequently, corresponding tertiary study groups and secondary professional committees were established under the Hydraulic Society and the Hydroelectric Power Society. Due to the cross-industry nature of geosynthetics technology, after years of application, finally approved by the Ministry of Civil Affairs, the national "China Geosynthetics Engineering Association" was formally established in 1995, led by the Ministry of Water Resources.

In addition, as early as 1986, three representatives from my country participated in the 3rd International Geosynthetics Academic Conference held in Vienna, hosted by the International Geosynthetics Society IGS. Through the application, IGS officially accepted my country as the 6th member country of the organization in 1990, and established the China Committee of International Society (CCIGS), which is responsible for international communication and technical exchange.

During this period, new product development and application fields of geosynthetic materials continued to expand, such as the introduction of geotextile bags for environmental protection as embankments; the use of geotextile bags to replace straw bales for flood control and rescue; the use of geotechnical membranes as shallow layers (such as less than 15m) vertical anti-seepage curtain instead of concrete anti-seepage wall; use geotextile and glass fiber mesh to prevent road cracking; use EPS to control frost heave; use geocells to build roads in desert areas to fix sand, and lay soft drainage pipes to improve soft foundation, And the promotion of geotechnical vegetation net to improve the environment and ecology, etc., have achieved effective results.

(4) Entering the standardization period

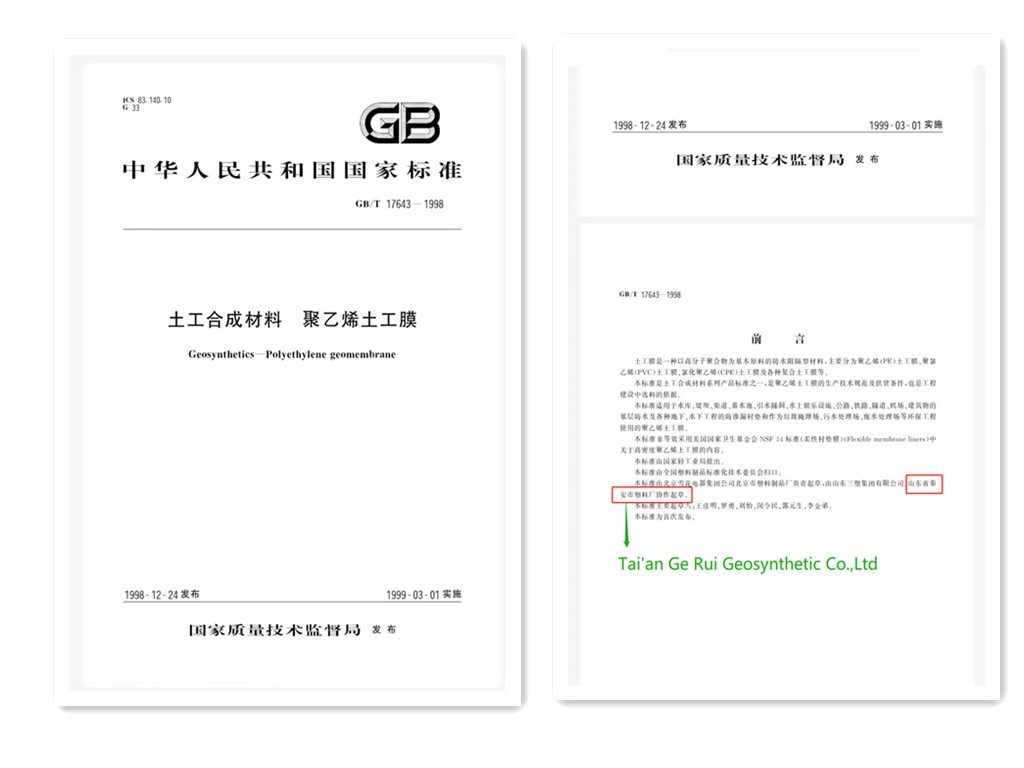

1998 was an extraordinary year, when the military and civilians overcame the catastrophic flood in history. Comrade Zhu Rongji, who was then prime minister, witnessed the material played a significant role in flood control and rescue during his inspection of the flood fight. Therefore, in his many written instructions after the hearing, he requested that the material and technology should be given priority in the repair of flood-damaged dams. Corresponding standards and driving down product prices. The Ministry of Water Resources took the lead in compiling the technical specifications for the application of geosynthetics, ending the state of no standards in my country. Subsequently, national standards and industrial technical standards for railways, highways, and water transportation were released; product standards and material testing standards followed. At the end of 1998, geosynthetics and technology entered a period of standardization.

In 1998, floods wreaked havoc along the Yangtze River in southern China, causing great losses to the country and its people. Premier Zhu Rongji visited the front line, because of the excellent characteristics of geomembrane, China government began to pay attention to the production and application of geomembrane, and asked GERUI to work with Beijing to compile geomembrane production standards.

GERUI GROUP adopts 100% virgin resins from USA company in the Middle East and special formulated same with SOLMAX company. The products produced by our factory are highly recognized bcs of the superior performance (the service life is 50% more than the general manufacturers).

Features:

* Excellent chemical resistance.

* Outstanding stress crack capacity.

* Lowest permeability.

* Excellent UV resistance.

* Stable low temperature embrittlement resistance.

* Complete width and thickness.

* Cost effective.

* Proven performance.

* Fast deployment.

* Easy transportation.

* Meet or exceed all aspects of GRI GM13.

3. Outlook

1) Development prospects

1) The raw materials of geosynthetic materials come from by-products such as coal, oil and natural gas, which are rich in material sources and manufactured in factories. If they are used properly, they can greatly replace ecological destruction such as excavation of earth and stones and felling of trees, which is in line with the general direction of environmental protection and sustainable development. .

2) The material can be produced according to human will to a certain extent, has many functions, and is light in weight, convenient in transportation, simple in construction, good in durability and low in price. It is a good building material and has broad development prospects. Today's "Eleventh Five-Year Plan" project, the western development, the South-to-North Water Diversion and the construction of a new socialist countryside are all very useful.